Troubleshooting and Meter Skills

Scope

Using a multimeter and diagnosing circuit faults are not fire alarm-specific skills.

I've spent my career in fire alarm, access control, video surveillance, intrusion detection/alarm, and building automation/energy management. But mostly fire alarm. As a result many of my examples are from the fire alarm industry. Nevertheless, this topic applies to any low voltage controls trade.

These skills are universally applicable. I've trained BAS, security, and of course fire alarm techs on troubleshooting and meter skills. Other trades who this fits include industrial automation, AV, nurse call, gate and overhead door controls, stage lighting and theatrical controls, solar PV, car wash controls, fuel dispensing systems, telecom, data center infrastructure, and many more.

Problem

When I oversaw Operations, I was regularly astonished by how many technicians struggled to use a multimeter effectively, even for basic tasks. Now that I've been teaching for a while, I guess I shouldn't have been surprised. Even 20-year techs often find diagnosing a simple open circuit or ground fault challenging.

I had one job where the tech relocated a pull station for an FM-200 suppression system in a data center for a multibillion-dollar oil and gas company. Afterward, there was a ground fault on the system. Trying his best to meter the circuits and determine the cause, he placed his meter probes across the manual release circuit while in Ohmmeter mode. This instantly tripped the EPO (emergency power off) to the room and fired the releasing circuit for the FM-200. To make matters worse, it was the Friday before their annual shareholder meeting. Legal and Finance teams were already scheduled to work through the weekend to prepare for the big event on Monday. We had just shut down servers that hadn't been turned off in decades, necessitating long nights and painful manual effort so they could meet their deadline.

Not every poor use of a multimeter was that expensive. Sometimes it just meant working through Thanksgiving to find all the ground faults and reverse polarity wiring at a new storage facility.

Poor troubleshooting and meter skills didn't just affect my teams' installation projects. Service customers found it frustrating, too, when the tech either repeatedly failed to find the problem or misdiagnosed the problem altogether.

I can't tell you how many times I had a tech say the panel was bad only to find that the trouble didn't go away after they replaced the panel. When that happened, the customer invariably expected us to eat the cost of the unneeded panel we had just installed. Then they usually wanted us to continue diagnosing the issue for free. To add insult to injury, we often had to pull a more skilled technician off of other work, jeopardizing our relationship with other customers. Once the issue was finally found and fixed, we then spent the next several years earning back the customer's trust.

As a manager, I occasionally had the opportunity to observe other technicians use a meter to troubleshoot circuit faults. More often than not, I was mortified. Senior technicians with a decade or more of field experience routinely demonstrated a fundamental lack of understanding of what they were doing.

Most Companies Aren't Teaching These Skills Well

I blame the industry as a whole for the lack of meter skills among our techs. In the low voltage skilled trades, we haven't done a good job of teaching critical skills like how to use a multimeter and how to diagnose circuit faults. Training tends to be unstructured, ad hoc, and very short. It's also often the blind leading the blind.

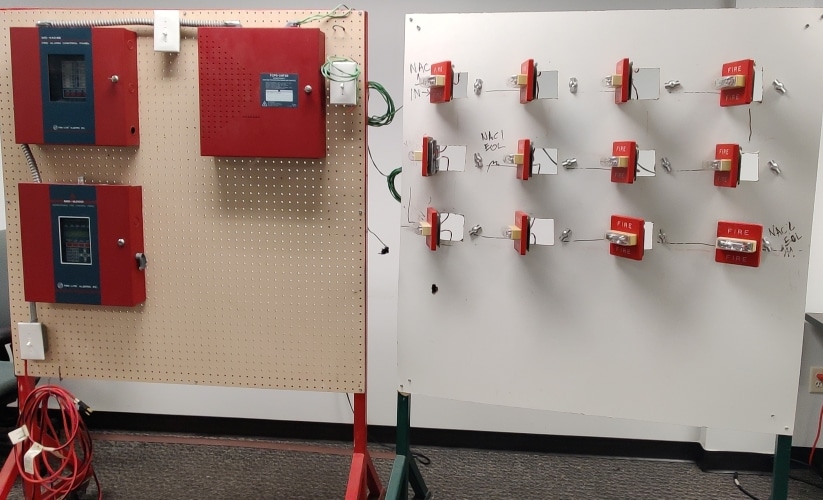

Even when a company has a training room set up, it's rarely ideal for teaching troubleshooting and meter skills. Most training rooms I've seen have just one or a small handful of devices on each circuit. That's not effective for teaching real world meter skills, like how to find a ground fault on a t-tapped circuit with 20+ devices. Additionally, the devices in most training rooms are typically mounted to the wall with the wiring concealed (like a regular building). That's not conducive to quickly and repeatedly introducing and troubleshooting various circuit faults.

I know my experiences aren't unique. Companies all across the industry are suffering the pain of additional work, cost, and headaches because their technicians don't know how to properly use a meter and troubleshoot faults.

Previous Solution and Results

In 2010, I built a troubleshooting board for a fire alarm troubleshooting and meter skills class. I still have access to that old board and used it to teach a dozen techs in February, 2025.

Here's what the old board looked like. I added hinges to mud rings so it would be easy to get to the back of the strobes (I wasn't focused on security or other trades yet).

Only 2 techs found the circuit fault I set up for them at the beginning of the class.

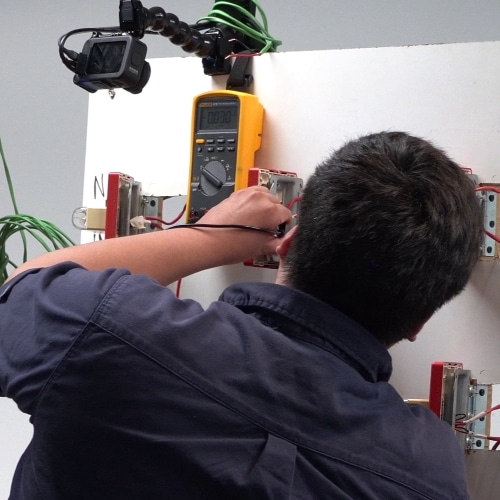

After the initial assessment, we jumped into training, which includes animations, interactive circuit demos, and more hands-on practice with the troubleshooting board. When working at the troubleshooting board, I use a GoPro to project the meter display onto the screen so the whole class can see what I am doing (or whoever is at the board).

The back of the board is set up to allow me to easily create circuit faults. I even had a Starbucks sleeve stapled to the back so I could put a cup of water there and create a ground fault through water.

This is one of my favorite classes because of the immediate results and how excited my students get when everything starts clicking.

By the end of the day, even sprinkler techs who had never used a meter were quickly finding circuit faults. Experienced techs who thought they were pretty good saw their resolution times fall to record lows.

I ended the training with a competition. Everyone succeeded in quickly finding the fault. The average completion time was just 37 seconds. The three fastest times were 20, 21 and 22 seconds.

New Solution

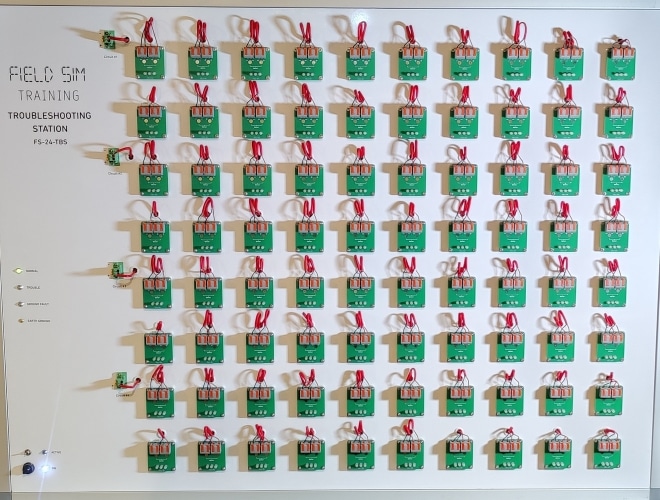

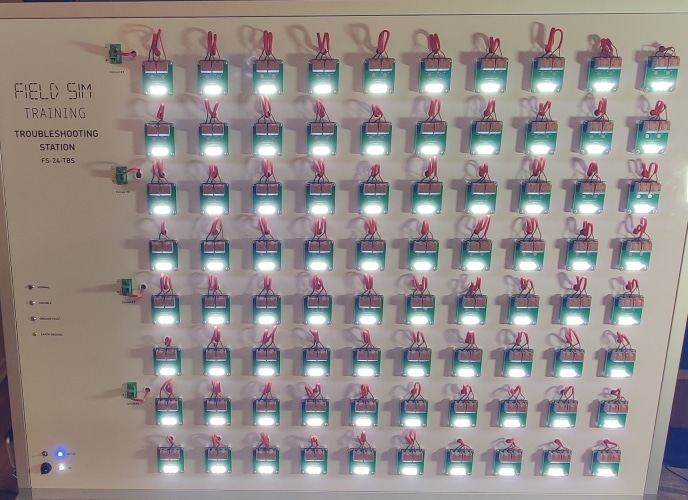

This is such an impactful class that I spent 4 months building a new version of the troubleshooting board: the FS-24-TBS Troubleshooting Station. It has 80 devices across 4 circuits and can be used to teach any low voltage controls technician how to troubleshoot.

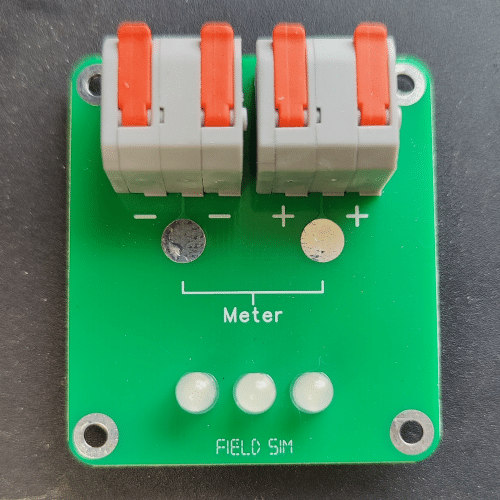

I invented my own device, the FS-24-LN. They represent things like strobes, door strikes, solenoids, actuators, relays, etc. I could have made them input sensors, but that would have merely complicated things without improving knowledge transfer.

Because we’re not here to learn how to screw and unscrew wire terminals, the FS-24-LN employs lever-operated wire terminals, making it fast to remove and reinstall wires. This allows students to spend more time with a meter and less time tightening and loosening terminals.

To make metering the circuit even faster, each FS-24-LN has meter pads directly on the front, enabling students to quickly meter voltage and resistance without removing the wires.

To further extend the simulation of real field components, every FS-24-LN illuminates when activated.

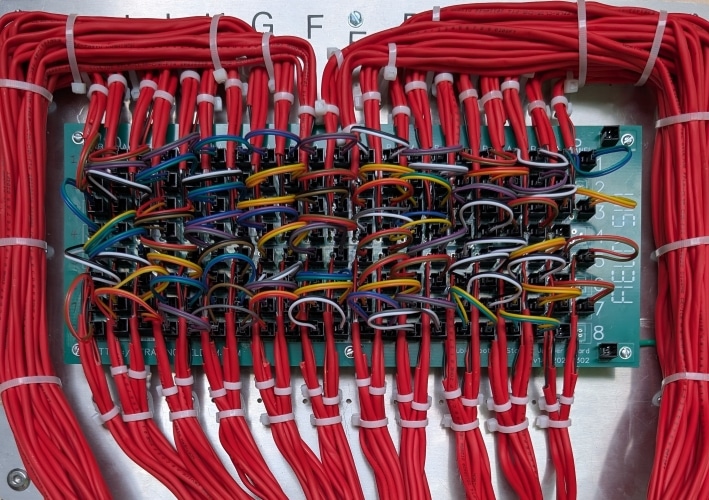

The back of the FS-24-TBS Troubleshooting Station is set up so I can introduce shorts, opens, ground faults, and reverse polarity. This is similar to my original board from 2007, but with nearly 7x the devices and in a more compact form. With this many devices and possible simultaneous fault conditions, I can create over 140 googol (14 x 10100) fault configurations.

Students are presented with a UI that should be familiar to most technicians. This includes Normal, Trouble, and Ground Fault LEDs and an earth ground reference screw.

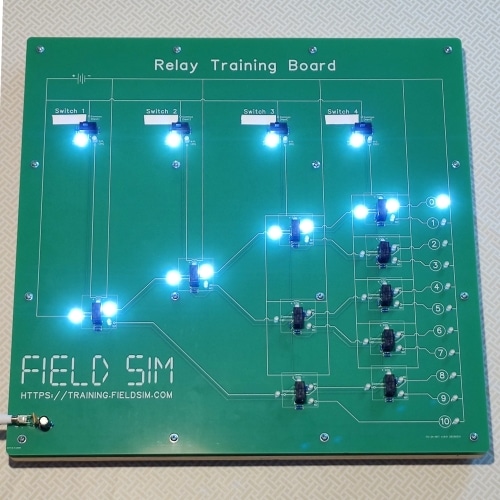

Relay Training Board

I also designed and built a board for teaching how to read one-line electrical diagrams and how to work with relays, the FS-5-BFT. You'll have to come to class to learn the secret hidden behind the labels at each switch.

Interactive Circuit Simulator and Custom Video Game

To further enhance the learning experience, I use an interactive circuit simulator and a custom video-game that I created.

Audience

This class is perfect for any low voltage controls technician whose role requires using a multimeter.

Course Summary

In the Field Sim Troubleshooting and Meter Skills course, students start by learning electrical foundations and basic meter skills. By the end of Day 1 (Foundations), students should be able to find an open or short circuit faster than most people you’ve ever seen. They should also have some proficiency at troubleshooting ground faults and reverse polarity.

Students who return for Day 2 (Full Course) will learn troubleshooting methods and more advanced faults, like intermittent faults and multiple simultaneous faults. Depending on time and class needs, they might get to practice diagnosing faults where the circuit path is unknown or doesn't match the drawing. Or they might get to practice diagnosing faults on circuits with T-Taps or ground faults through water. They will also get a lot more in-depth instruction in how to approach troubleshooting. And they will get to use the FS-5-BFT Relay Training Board to learn how to read basic one-line DC electrical diagrams to determine relay operation.

Click on either of the links below to learn more about the one and two-day versions of the course and see dates for upcoming instructor-led classes. We're also available for private instruction. Please reach out if you'd like to schedule a class dedicated for just your company.

Troubleshooting and Meter Skills Foundations

In this 1-day class, students learn and practice a repeatable process to find simple faults like solid opens, shorts, reverse polarity, and ground faults, using a digital multimeter. Students get to engage with interactive simulations and practice hands-on with the FS-24-TBS Troubleshooting Station. More details...

Course length: 1 day

(0.8 CEU)

Price: $500

Troubleshooting and Meter Skills Full Course

This 2-day class includes all the material from the 1-day Foundations class. When they return for the second day, students learn to address more difficult problems, like intermittent faults and ground faults through water. Students also learn to read one-line electrical drawings and understand relays via hands-on interaction with the FS-5-BFT Relay Training board. More details...

Course length: 2 days

(1.6 CEU)

Price: $1000